Babu bushewa extrusion granulation samar line

Layin samar da granular extrusion mara bushewa tsari ne na samar da taki mai granulated ba tare da buƙatar tsarin bushewa ba.Wannan tsari yana amfani da haɗin fasahar extrusion da granulation don ƙirƙirar granules na taki mai inganci.

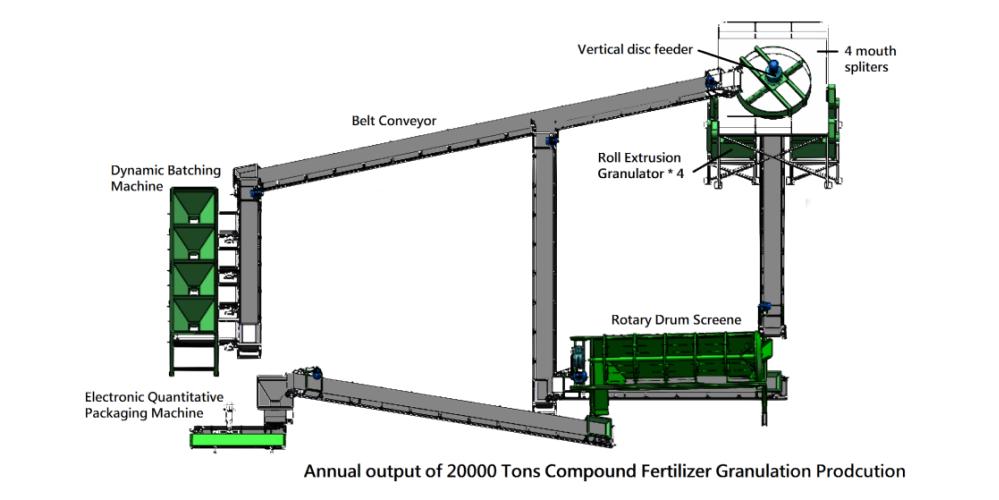

Anan ga cikakken jita-jita na layin samar da granulation ba bushewa ba:

1.Raw Material Handling: Mataki na farko shine tattarawa da sarrafa albarkatun ƙasa.Danyen kayan da ake amfani da su wajen samar da takin zamani na iya hada da takin nitrogen, phosphorus, da potassium (NPK), da sauran kayan da ba a iya amfani da su ba kamar takin dabbobi, ragowar amfanin gona, da kayayyakin masana’antu.

2.Crushing: Daga nan sai a niƙa kayan da ake amfani da su zuwa kanana don sauƙaƙa aikin hadawa.

3.Mixing: Abubuwan da aka murƙushe suna haɗuwa tare ta amfani da na'ura mai haɗawa don ƙirƙirar cakuda mai kama.

4.Extrusion Granulation: Abubuwan da aka gauraye ana ciyar da su a cikin granulator extrusion, wanda ke amfani da babban matsin lamba da dunƙule ko rollers don damfara kayan cikin ƙananan pellets ko granules.Za a yanke pellets ko granules da aka fitar zuwa girman da ake so ta amfani da abin yanka.

5.Cooling da Screening: The extruded granules sa'an nan sanyaya da kuma tace su cire duk wani oversize ko m barbashi, tabbatar da daidaito samfurin.

6.Coating: Sannan an rufe granules ɗin da aka zana tare da Layer na kayan kariya don hana caking da haɓaka rayuwar ajiya.Ana iya yin wannan ta amfani da injin rufewa.

7.Package: Mataki na ƙarshe shine kunshin granules a cikin jaka ko wasu kwantena, shirye don rarrabawa da siyarwa.

Amfanin layin samar da granulation ba bu bushewa sun haɗa da ƙarancin amfani da makamashi da rage tasirin muhalli idan aka kwatanta da hanyoyin bushewa na gargajiya.Bugu da ƙari, wannan tsari zai iya samar da taki mai granulated tare da daidaitaccen girman barbashi da abun ciki na gina jiki, wanda zai iya inganta ingantaccen taki da amfanin gona.

Overall, wani babu-bushewa extrusion granulation samar line iya zama wani ingantaccen da kuma kudin-tasiri hanya na samar da high quality-granulated taki.Koyaya, ana iya buƙatar takamaiman kayan aiki da injina don samar da granules tare da halayen da ake so.