Cikakken tsarin samar da layin faifai iri-iri yana ɗaya daga cikin manyan fa'idodin masana'antar Henan Zheng Heavy.Yana iya samar da cikakken kuma abin dogara samar line mafita bisa ga ainihin bukatun abokan ciniki.

Muna da gogewa a cikin tsarawa da sabis na layukan samar da taki iri-iri.Ba wai kawai muna mayar da hankali ga kowane hanyar haɗin yanar gizo ba a cikin tsarin samarwa, amma kuma koyaushe muna fahimtar cikakkun bayanai game da kowane tsari akan duk layin samarwa da samun nasarar samun haɗin kai.

Layin samar da faifai granulator ana amfani dashi galibi don samar da taki.Ana iya yin takin gargajiya da taki na dabbobi da na kaji, sharar gona da datti na birni.Ana buƙatar ƙarin sarrafa waɗannan sharar gida kafin a canza su zuwa takin gargajiya na kasuwanci na siyarwa.Zuba jarin mai da sharar gida ya zama dukiya yana da fa'ida sosai.

Layin samar da takin zamani na diski granulated ya dace da:

- ►Kerar da takin naman sa taki

- ►Kera alade taki Organic taki

- ►Kera kaza da agwagwa taki Organic taki

- ►Tumaki taki Organic taki masana'antu

- ►Organic taki masana'antu na birane sludge

1. Takin dabba: taki kaji, taki alade, takin tumaki, takin saniya, takin doki, takin zomo, da sauransu.

2. sharar da masana'antu: inabi, vinegar slag, rogo saura, sugar saura, biogas sharar gida, Jawo saura, da dai sauransu.

3. Sharar noma: bambaro, garin waken soya, garin auduga, da sauransu.

4. Sharar gida: dattin kicin

5. sludge: sludge na birni, sludge kogi, sludge tace, da dai sauransu.

Layin samar da faifan diski yana ci gaba, inganci da aiki, tsarin kayan aiki yana da ƙarfi, sarrafa kansa yana da girma, kuma aikin yana da sauƙi, wanda ya dace da yawan samar da takin gargajiya.

1. Ana amfani da kayan aikin lalata da lalacewa a duk kayan aikin samar da kayan aiki.Babu hayakin sharar gida uku, ceton makamashi da kare muhalli.Yana gudana a hankali kuma yana da sauƙin kulawa.

2. Ana iya daidaita ƙarfin samarwa bisa ga bukatun abokin ciniki.Tsarin duk layin samarwa yana da ɗan ƙaramin ƙarfi, kimiyya da ma'ana, kuma fasahar ta ci gaba.

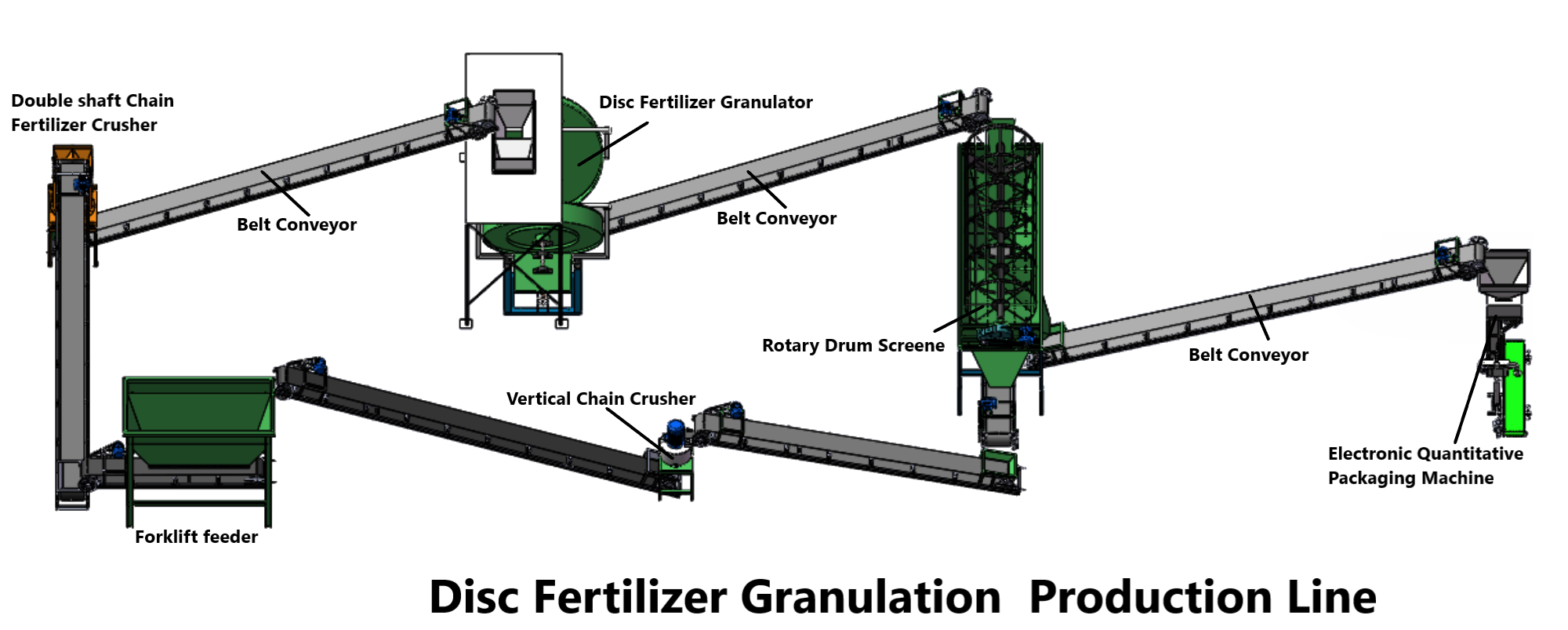

Kayan aikin layin granulation na diski sun haɗa da sinadarai → blender (sirring) → injin granulation faifai (granulator) → na'urar sieve (bayyana samfuran da ba su da inganci daga samfuran da aka gama) haɗi zuwa matakai daban-daban).

Lura: wannan layin samarwa don tunani ne kawai.

Tsarin tafiyar da layin samar da faifai granulation yawanci ana iya raba shi zuwa:

1. Raw kayan sinadaran tsari

Matsakaicin rabon albarkatun ƙasa na iya tabbatar da ingancin taki mai girma.Danyen kayan sun hada da najasar dabba, ruɓaɓɓen 'ya'yan itace, bawo, ɗanyen kayan lambu, koren taki, takin teku, takin gona, sharar gida uku, ƙananan ƙwayoyin cuta da sauran albarkatun ƙasa.

2. Raw kayan hadawa tsari

Ana gauraya duk kayan albarkatun kasa kuma ana motsa su daidai a cikin blender.

3. Karye tsari

A tsaye sarkar crusher murkushe manyan kayan cikin kananan guda waɗanda zasu iya biyan buƙatun granulation.Sa'an nan mai ɗaukar bel ɗin ya aika kayan cikin injin granulation diski.

4. Tsarin granulation

The faifai kusurwa na faifai granulation inji rungumi dabi'ar arc tsarin, da kuma ball form rate iya isa fiye da 93%.Bayan kayan ya shiga cikin farantin granulation, ta hanyar ci gaba da jujjuyawar faifan granulation da na'urar fesa, kayan yana haɗawa tare da juna don samar da barbashi tare da sifa mai kama da kyan gani.

5. Tsarin dubawa

Ana jigilar kayan da aka sanyaya zuwa injin abin nadi don nunawa.Ingantattun samfuran za su iya shiga cikin ɗakunan ajiya da aka gama ta hanyar jigilar bel, kuma ana iya haɗa su kai tsaye.Abubuwan da ba su cancanta ba za su dawo su sake dawowa.

6. Tsarin marufi

Marufi shine tsari na ƙarshe na layin samar da taki.An haɗe samfurin da aka gama tare da cikakkiyar injin marufi mai ƙididdigewa.Babban digiri na aiki da kai da babban inganci ba kawai cimma daidaiton aunawa ba, har ma da kyau kammala aikin ƙarshe.Masu amfani za su iya sarrafa saurin ciyarwa kuma saita sigogin sauri bisa ga ainihin buƙatu.