Ɗaya daga cikin manyan fa'idodin yin aiki tare da Yi Zheng shine cikakken ilimin tsarin mu;mu ba masana ne kawai a wani bangare na tsari ba, a maimakon haka, kowane bangare.Wannan yana ba mu damar samar wa abokan cinikinmu hangen nesa na musamman game da yadda kowane ɓangaren tsari zai yi aiki tare gaba ɗaya.

Za mu iya samar da cikakken tsarin granulation, ko guda guda na kayan aiki duka biyu inorganic da Organic aikace-aikace.

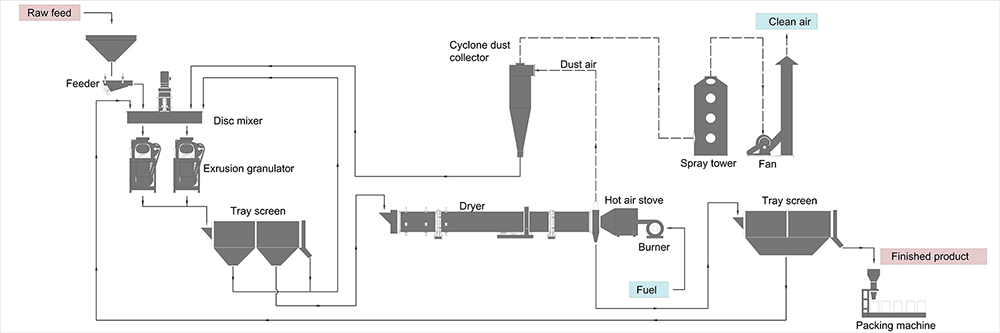

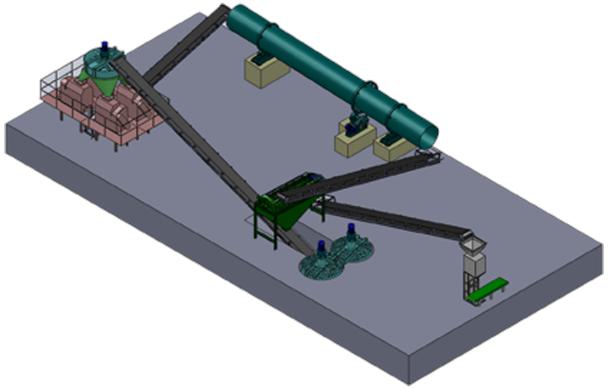

Za mu iya samar da tsari zane da wadata da dukan no-bushewa extrusion fili taki samar line.Kayan aiki sun haɗa da Hopper & Feeder, nadi (Extrusion) Granulator, Rotary Screen, Bucket Elevator, Conveyor Belt, Injin Packing da Scrubber.

Wannan Nadi (Extrusion) granulator samar line iya samar da high, matsakaici da kuma low mayar da hankali fili taki ga iri-iri amfanin gona.Tare da nau'i biyu na granulator don samar da granules, layin samarwa baya buƙatar tsarin bushewa, yana da ƙananan zuba jari da ƙarancin wutar lantarki.Ana iya tsara rollers na latsawa na granulator don yin siffofi daban-daban da girman kayan.Layin ya haɗa da injin batching na atomatik, masu jigilar bel, masu haɗa kwanon rufi, mai ba da kwanon rufi, ƙwanƙwasa ƙwanƙwasa, na'ura mai jujjuyawar nuni, ɗakunan ajiya na samfuran da aka gama, da injin tattara kaya ta atomatik.Muna shirye don bayar da kayan aikin taki mafi aminci da mafita mafi dacewa ga abokan cinikinmu masu daraja.

Amfani:

1. Ɗauki matsa lamba na inji don samar da granules, babu buƙatar zafi ko humidify albarkatun kasa

2. Ya dace da kayan zafi mai zafi, irin su ammonium bicarbonate

3. Babu buƙatar tsarin bushewa, ƙananan zuba jari, rashin amfani da wutar lantarki.

4.Babu sharar ruwa ko iskar gas, babu gurbatar muhalli.

5. Uniform barbashi size rarraba, babu agglomeration.

6. Ƙaƙwalwar ƙayyadaddun ƙayyadaddun tsari, fasaha mai mahimmanci, aikin barga, kulawa mai sauƙi.

7. Sauƙaƙe aiki, mai sauƙin gane sarrafawa ta atomatik, haɓaka haɓakar samarwa.

8. Wide albarkatun kasa aikace-aikace kewayon, babu musamman kaddarorin bukata

Proce

1. Injin Batching Na atomatik

Da fari dai, nau'ikan kayan daban-daban suna daidaita daidai da dabara ta injin batching 5 bins, wanda zai iya kammala kayan batching ta atomatik tare da inganci mai inganci da inganci, don haka ana tabbatar da ingancin taki.Bayan batching, ana isar da kayan zuwa mahaɗin kwanon rufi.

2. Disc Mixer

Mun ɗauki nau'i biyu na masu haɗa diski a cikin wannan layin samar da taki.Mai rage cycloidal yana motsa babban igiya don juyawa, kuma bi da bi yana korar makamai masu tayar da hankali.Tare da tayar da makamai masu tayar da hankali da ƙananan shebur akan su, kayan albarkatun suna cike da haɗuwa.Bayan haɗuwa, ana fitar da kayan daga fitarwa a ƙasa.Gefen ciki na diski yana ɗaukar farantin polypropylene ko bakin karfe, wanda ke sa kayan ba su da sauƙi cikin sauƙi, da juriya na abrasion.

3. Nadi biyu taki Granulator

Ta hanyar mai ɗaukar bel ɗin, ana isar da albarkatun da aka gauraye da kyau zuwa ga mai ciyar da kwanon rufi, wanda ke ciyar da kayan daidai gwargwado cikin granulators guda huɗu da ke ƙarƙashin mai ciyarwa ta hopper.By counter-juyawa high matsa lamba rollers, kayan suna extruded cikin yanka.Yanke-yanke suna gangarowa zuwa ɗakin murƙushewa a ƙarƙashin abin nadi, inda ake murƙushe su ta hanyar murƙushe rollers kuma ana dubawa don samun granular da ake buƙata.Masu aikin latsa suna ɗaukar sabon nau'in ƙarfe wanda ke da juriya ga lalata, lalacewa da tasiri.

4. Rotary Screening Machine

Ta hanyar mai ɗaukar bel ɗin, ana aika granules daga granulator na extrusion zuwa na'ura mai jujjuya, inda granules waɗanda ba su cancanta ba suka wuce ta buɗewar allo da fitarwa ta hanyar kanti a ƙasa, sannan a mayar da su zuwa ga mai ba da kwanon rufi, yayin da ƙwararrun granules ke gudana ta hanyar. da kanti a ƙananan ƙarshen na'ura da kuma isar da shi zuwa ga kammala kayayyakin sito.

5. Na'urar tattarawa ta atomatik

Ta wurin ɗakunan ajiya da aka gama, ana auna ƙwararrun granules da na'urar tattara kaya ta atomatik.Naúrar ta ƙunshi injin aunawa ta atomatik da na'urar tattara kaya, na'urar jigilar kaya, na'urar rufewa da mai ciyarwa.Yana da fasalulluka na ma'aunin ma'auni mai girma, aiki mai ƙarfi, ƙarancin wutar lantarki, da ƙaramin zama na ƙasa.

Lokacin aikawa: Satumba-27-2020