Ɗaya daga cikin manyan fa'idodin yin aiki tare da Yi Zheng shine cikakken ilimin tsarin mu;mu ba masana ne kawai a wani bangare na tsari ba, a maimakon haka, kowane bangare.Wannan yana ba mu damar samar wa abokan cinikinmu hangen nesa na musamman game da yadda kowane ɓangaren tsari zai yi aiki tare gaba ɗaya.

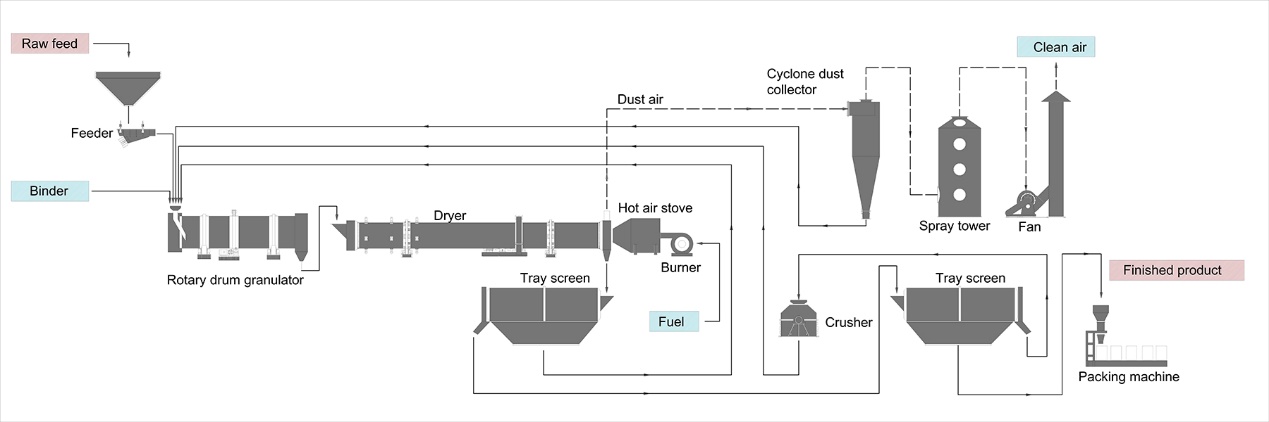

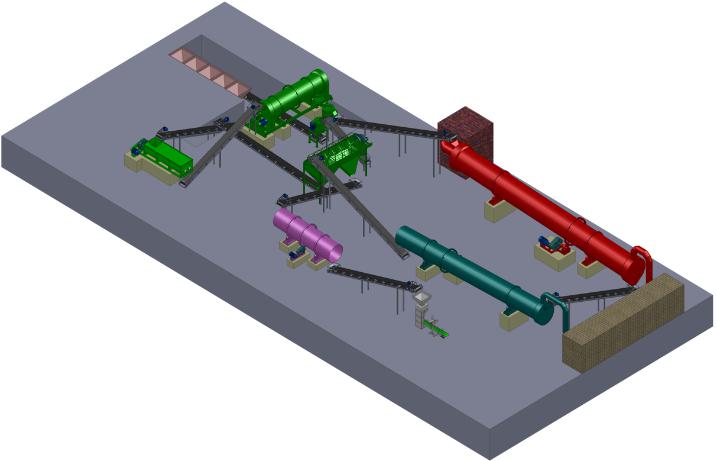

Za mu iya samar da tsari zane da kuma samar da wani Rotary drum granulation samar line.

Wannan layin samarwa na Rotary Drum Granulation yana sanye take da injin batching, mahaɗa biyu-shaft, rotary drum granulator, sarkar bushewa, bushewar drum & mai sanyaya, na'urar tantance drum mai jujjuya da sauran kayan aikin taki.Abubuwan da ake fitarwa na shekara-shekara na iya zama ton 30,000.Kamar yadda wani kwararren taki samar line manufacturer, mu kuma samar da abokan ciniki da sauran granulation Lines da daban-daban samar iya aiki, kamar 20,000 T / Y, 50,000T / Y, da kuma 100,000T / Y, da dai sauransu.

Amfani:

1. Ya karɓi ci-gaba mai jujjuya drum granulator, ƙimar granulation na iya kaiwa 70%.

2. Maɓalli masu mahimmanci sun ɗauki kayan da ba su da lalacewa da lalata, kayan aiki suna da tsawon rayuwar sabis.

3. Ɗauki farantin filastik ko bakin karfe, kayan da ba su da sauƙi don tsayawa a bangon ciki na na'ura.

4. Ƙarfafa aiki, kulawa mai sauƙi, babban inganci, ƙananan amfani da makamashi.

5. Ɗauki mai ɗaukar bel don haɗa dukkan layin, fahimtar ci gaba da samarwa.

6. Ɗauki ɗakuna guda biyu na ƙura don ma'amala da iskar gas ɗin wutsiya, yanayin yanayi.

7. Sau biyu na tsarin nunawa tabbatar da ƙwararrun granules tare da girman uniform.

8. Ko da yaushe hadawa, bushewa, sanyaya, da kuma shafi, da ƙãre samfurin yana da m inganci.

Tsarin tsari:

Raw kayan batching (Static batching Machine) → Hadawa (Maɗaukakin Shaft Biyu) → Granulating (Rotary Drum granulator) → bushewa (na'urar bushewa mai jujjuya) → Sanyaya (mai sanyaya ganga mai jujjuya) → Kammala aikin nunawa (na'ura mai jujjuya ganga) → Sub-standard granules crushing (a tsaye sarkar taki sarkar crusher) → Rufi (na'ura mai jujjuya ganga) → Kammala kayan tattarawa (nau'in ƙididdiga ta atomatik) → Adana (ajiya a wuri mai sanyi da bushewa)

SANARWA:Wannan layin samarwa don tunani ne kawai.

1.Raw kayan batching

Dangane da buƙatun kasuwa da sakamakon ƙayyadaddun ƙasa na gida, za a ware albarkatun ƙasa kamar urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, calcium mai nauyi, babban calcium) da potassium chloride (potassium sulphate) a wani kaso.Abubuwan da ake ƙarawa da abubuwan ganowa ana auna su ta hanyar ma'aunin bel kuma an daidaita su zuwa wani yanki.Dangane da tsarin dabara, duk albarkatun ƙasa suna haɗe daidai da mahaɗin.Ana kiran wannan tsari premix.Yana tabbatar da ingantaccen tsari kuma yana ba da damar inganci da ci gaba da batching.

2.Hadawa

Cikakkun haɗa kayan da aka shirya da kuma motsa su daidai gwargwado, wanda ke kafa tushe don ingantaccen taki mai inganci da inganci.Ana iya amfani da mahaɗar tsaye ko mahaɗar diski don ko da haɗawa.

3.Materials Granulating

Bayan murkushe, ana jigilar kayan zuwa cikin jujjuyawar ganga ta hanyar jigilar bel.Tare da jujjuyawar ganga akai-akai, kayan sun zama gadon birgima, kuma suna tafiya tare da wata hanya.Ƙarƙashin ƙarfin extrusion da aka samar, kayan suna haɓaka cikin ƙananan ƙwayoyin cuta, waɗanda suka zama ainihin, suna haɗa foda a kusa da su don samar da ƙwararrun nau'in nau'in nau'i.

4.Bushewar taki

Za a bushe kayan aiki bayan granulating don isa daidaitaccen abun cikin ruwa.Lokacin da na'urar bushewa ke juyawa, jerin fins na ciki za su ɗaga kayan ta hanyar rufe bangon ciki na bushewa.Lokacin da kayan ya kai tsayin tsayi don mirgine fins baya, za a sake fadowa zuwa kasan na'urar bushewa, sa'an nan kuma ta ratsa cikin rafin gas mai zafi yayin da yake fadowa.Tsarin ƙiyayyar iska mai zaman kansa, daidaita fitar da sharar gida yana haifar da kuzari da ceton farashi.

5.Cooling taki

Rotary drum cooler yana cire ruwan taki da rage zafin jiki, ana amfani da shi tare da na'urar bushewa a cikin takin gargajiya da samar da takin zamani, wanda ke ƙara saurin sanyi sosai, kuma yana sauƙaƙa haɓaka aikin.Hakanan ana iya amfani da na'urar sanyaya rotary don sanyaya sauran kayan foda & granular.

6.Fertilizer Screening: Bayan sanyaya, duk nau'in granules da ba su cancanta ba ana nunawa ta na'urar tantancewar juyi da jigilar bel zuwa mahaɗin sannan a haɗe su da sauran albarkatun ƙasa don sake sarrafawa.Za a kai kayan da aka gama zuwa injin ɗin da ake shafa taki.

7. Rufewa: Ana amfani da shi ne musamman don rufe saman ƙananan granules tare da fim mai kariya na uniform don ƙaddamar da lokacin adanawa yadda ya kamata da kuma sa granules sumul.Bayan shafa, a nan zuwa ga tsari na ƙarshe - marufi.

8. Marufi tsarin: Atomatik marufi marufi inji aka soma a cikin wannan tsari.Na'urar ta ƙunshi na'ura mai aunawa ta atomatik da na'ura mai ɗaukar nauyi, tsarin jigilar kaya, injin rufewa da sauransu.Hakanan ana iya daidaita Hopper bisa ga buƙatun abokin ciniki.An yi amfani da kididdigar kididdigar manyan kayan aiki kamar takin gargajiya da takin gargajiya da aka yi amfani da su sosai a cikin masana'antu da filayen daban-daban.

Lokacin aikawa: Satumba-27-2020