IGabatarwar Layin Samar da Taki na Compound

Compound taki shine taki mai dauke da sinadirai biyu ko uku na N, P;K. Haɗin takin yana samuwa a cikin foda ko granular form.Yawancin lokaci ana amfani dashi azaman kayan shafa kuma ana iya amfani dashi azaman taki na tushe da takin iri.Haɗin takin yana ƙunshe da abubuwa masu inganci, don haka yana da sauƙin narkewa a cikin ruwa, yana saurin rubewa, kuma cikin sauƙi na tushen tsarin, don haka ana kiransa "taki mai sauri".Ayyukansa shine saduwa da cikakken buƙatu da daidaita nau'ikan abubuwan gina jiki da amfanin gona ke buƙata a ƙarƙashin yanayi daban-daban.

Wannan layin samar da taki ana amfani da shi ne musamman don granulate granules taki ta amfani da kayan NPK, GSSP, SSP, granulated potassium sulfate, sulfuric acid, ammonium nitrate, da sauransu.Kayan aikin taki na fili yana da fa'ida na gudana barga, ƙarancin aiki mara kyau, ƙaramin kulawa da ƙarancin farashi.

Duk layin da ake samarwa yana sanye da na'urori masu inganci kuma masu inganci, wanda zai iya samun fitowar tan 50,000 na takin zamani a duk shekara.Dangane da ainihin buƙatun ƙarfin samarwa, muna tsarawa da tsara layin samar da taki tare da ƙarfin shekara daban-daban na ton 10,000 ~ 300,000.Dukkanin saitin kayan aiki yana da ƙima, m, kimiyya, aikin barga, ceton makamashi, ƙarancin kulawa, mai sauƙin aiki, shine mafi kyawun zaɓi ga masana'antun taki.

Matsakaici fili taki samar da layin tsari

Ana iya raba tsarin samar da taki na fili zuwa gabaɗaya: batching albarkatun ƙasa, haɗawa, murƙushewa, granulating, gwajin farko, bushewar granule da sanyaya, nunawa na biyu, murfin granule da marufi.

1. Raw kayan batching: bisa ga kasuwa bukatar da gida kayyade sakamakon kasa, albarkatun kasa kamar urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, nauyi alli, general calcium) da potassium chloride ( potassium sulfate) za a kasafta shi a wani kaso.Abubuwan da ake ƙarawa da abubuwan ganowa ana auna su ta hanyar ma'aunin bel kuma an daidaita su zuwa wani yanki.Dangane da tsarin dabara, duk albarkatun ƙasa suna haɗe daidai da mahaɗin.Ana kiran wannan tsari premix.Yana tabbatar da ingantaccen tsari kuma yana ba da damar inganci da ci gaba da batching.

2. Cakuda: Cikakkun haɗa kayan da aka shirya sannan a jujjuya su daidai gwargwado, wanda ke kafa tushe don ingantaccen taki mai inganci da inganci.Ana iya amfani da mahaɗar tsaye ko mahaɗar diski don ko da haɗawa.

3. Crushing: Don murkushe caking a cikin kayan ya zama dole don sarrafa granulation na gaba.Ana amfani da injin murkushe sarka musamman.

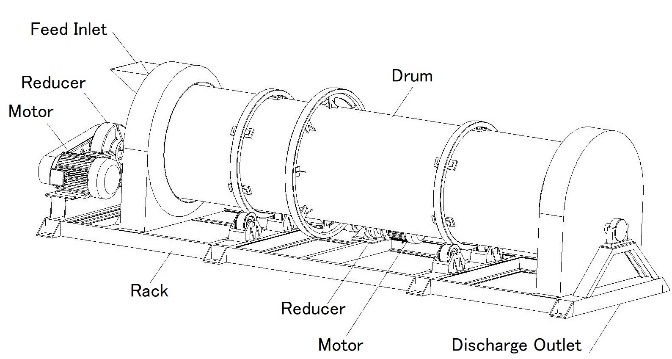

4. Granulating: A ko'ina zuga da murkushe kayan ana hawa zuwa granulator ta hanyar bel na'ura don granulating, wanda shi ne ainihin ɓangare na dukan samar line.Zaɓin granulator yana da matukar mahimmanci, muna da granulator diski, juzu'in drum granulator, abin nadi extrusion granulator ko fili taki granulator don zaɓi.

5. Nuni na farko: Ɗauki gwajin farko na granules, da mayar da waɗanda ba su cancanta ba zuwa murƙushewa don sake sarrafa su.Gabaɗaya, ana amfani da na'urar tantancewar rotary.

6. bushewa: Ana jigilar ƙwararrun granules bayan gwajin farko ta hanyar jigilar bel zuwa na'urar bushewa don bushewa don rage ɗanɗanon abubuwan da aka gama.Bayan bushewa, danshi abun ciki na granules zai ragu daga 20% -30% zuwa 2% -5%.

7. Granules sanyaya: Bayan bushewa, za a aika da granules zuwa mai sanyaya don sanyaya, wanda aka haɗa tare da na'urar bushewa ta hanyar mai ɗaukar bel.Sanyaya zai iya cire ƙura, inganta yanayin sanyi da yanayin amfani da zafi, da kuma ƙara cire danshi a cikin taki.

8. Allon na biyu: Bayan sanyaya, duk nau'in granules ɗin da ba su cancanta ba ana tace su ta na'urar tantancewar rotary sannan a ɗauke su ta bel ɗin zuwa mahaɗin sannan a haɗe su da sauran albarkatun ƙasa don sake sarrafawa.Za a kai kayan da aka gama zuwa injin ɗin da ake shafa taki.

9. Rufewa: Ana amfani da shi ne musamman don rufe saman ƙananan granules tare da fim ɗin kariya na uniform don ƙaddamar da lokacin adanawa yadda ya kamata da kuma sa granules sumul.Bayan rufewa, a nan zuwa ga tsari na ƙarshe - marufi.

10. Marufi tsarin: Atomatik marufi marufi inji aka soma a cikin wannan tsari.Na'urar ta ƙunshi na'ura mai aunawa ta atomatik da na'ura mai ɗaukar nauyi, tsarin jigilar kaya, injin rufewa da sauransu.Hakanan ana iya daidaita Hopper bisa ga buƙatun abokin ciniki.An yi amfani da kididdigar kididdigar manyan kayan aiki kamar takin gargajiya da takin gargajiya da aka yi amfani da su sosai a cikin masana'antu da filayen daban-daban.

Fasaha da Halayen layin samar da taki:

Rotary drum granulator ana amfani dashi galibi a cikin samar da fasahar taki mai girma mai girma, ana iya amfani da diski mara tururi a cikin samar da babban, matsakaici da ƙarancin maida hankali na fasahar taki, haɗe da fasahar anti-caking, babban nitrogen. fasahar samar da takin zamani da dai sauransu.Layin samar da takin mu na fili yana da halaye masu zuwa:

1. Faɗin aikace-aikacen albarkatun ƙasa: ana iya samar da takin mai magani bisa ga tsari daban-daban da rabbai, kuma ya dace da samar da takin mai magani na kwayoyin halitta da inorganic.

2. Yawan samar da pellet mai girma da adadin tsira daga ƙwayoyin cuta: sabuwar fasaha na iya sa adadin pellet ɗin ya kai kashi 90% ~ 95%, kuma ƙarancin zafin jiki da fasahar bushewa da iska na iya sa adadin tsira daga ƙwayoyin cuta. kai 90%.Samfurin da aka gama yana da kyau a cikin bayyanar da daidaituwa a girman, 90% wanda shine granules tare da girman 2 ~ 4mm.

3. Matsakaicin tsari mai sassauƙa: Ana iya daidaita tsarin tafiyar da layin samar da taki bisa ga ainihin albarkatun ƙasa, dabara da kuma rukunin yanar gizon, kuma ana iya tsara kwararar tsari na musamman bisa ga ainihin bukatun.

4. Barga na gina jiki rabo na ƙãre kayayyakin: ta atomatik metering na sinadaran, m metering kowane irin m, ruwa da sauran albarkatun kasa, kusan kiyaye da kwanciyar hankali da kuma tasiri na duk na gina jiki a cikin dukan tsari.

COmpound Taki Production LineAikace-aikace

1. Sulfur mai rufi tsarin samar da urea.

2.Different irin Organic da inorganic taki tsari.

3.Acid fili taki granulation tsari.

4.Powdery masana'antu sharar gida inorganic taki tsari.

5.Large barbashi urea samar tsari.

6.Seedling Substrate taki samar da tsari.

Lokacin aikawa: Satumba-27-2020