Dry granulator

Busassun granulator, wanda kuma aka sani da injin busassun busassun, kayan aiki ne na musamman da aka tsara don granulation na busassun kayan bushewa ba tare da buƙatar masu ɗaure ruwa ko kaushi ba.Wannan tsari ya ƙunshi haɗawa da siffata busassun foda ko barbashi zuwa ɓangarorin, waɗanda ke da sauƙin sarrafawa, adanawa, da jigilar kaya.A cikin wannan labarin, za mu bincika fa'idodi, ƙa'idodin aiki, da aikace-aikacen busassun granulator a cikin masana'antu daban-daban.

Amfanin Dry Granulation:

Babu Liquid Binders or Solvents: Dry granulation yana kawar da buƙatun masu ɗaure ruwa ko kaushi da aka saba amfani da su a cikin rigar granulation.Wannan yana rage rikitaccen tsarin granulation, yana sauƙaƙe sarrafawa da tsaftacewa, kuma yana kawar da haɗarin ƙetare ko matsalolin muhalli da ke da alaƙa da tushen ruwa.

Ingantacciyar Kwanciyar Hankali: Busassun granules sun inganta kwanciyar hankali idan aka kwatanta da foda ko sassaukarwa.Halin ƙaƙƙarfan yanayi na granules yana rage rarrabuwa, yana hana ɗaukar danshi, kuma yana haɓaka kaddarorin kwarara.Wannan kwanciyar hankali yana tabbatar da daidaiton ingancin samfur kuma yana rage haɗarin lalacewa yayin ajiya ko sufuri.

Taimakon Kuɗi: Dry granulation yana ba da fa'idodin farashi ta hanyar kawar da buƙatar masu ɗaure ruwa, hanyoyin bushewa, da kayan haɗin gwiwa.Yana rage yawan amfani da makamashi, lokacin samarwa, da bukatun kiyayewa, yana haifar da tanadin farashi ga masana'antun.

Abubuwan da za a iya gyarawa na Granule: Dry granulation yana ba da izini daidaitaccen iko akan kaddarorin granule, kamar girman, siffa, yawa, da porosity.Wannan yana bawa masana'antun damar daidaita granules zuwa takamaiman buƙatun aikace-aikacen, yana tabbatar da ingantaccen aiki da halayen samfuran da ake so.

Ƙa'idar Aiki na Dry Granulators:

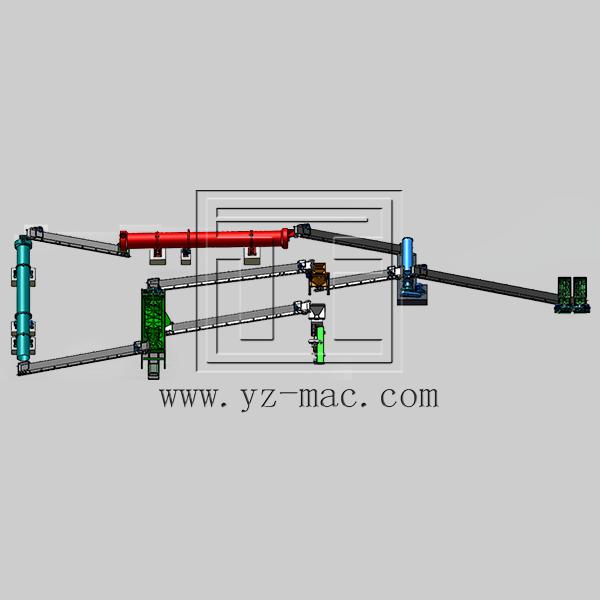

Busassun granulators yawanci suna amfani da manyan matakai guda biyu: ƙaddamarwa da niƙa.

Ƙunƙasa: A cikin matakin ƙaran, busassun foda ko barbashi ana ciyar da su a cikin ɗakin granulation, inda nau'i-nau'i na jujjuyawar juzu'i ko na'urar latsawa ta injina suna matsa lamba don ƙaddamar da kayan.Abun da aka haɗe yana jurewa nakasar filastik, yana samar da kintinkiri ko takarda.

Milling: Daga nan sai a bi ta hanyar injin niƙa, wanda ya ƙunshi saitin wuƙaƙe ko ruwan wukake waɗanda ke karya kayan zuwa granules na girman da ake so.Ana tattara granules ɗin da aka niƙa kuma suna iya ɗaukar ƙarin matakan sarrafawa, kamar sieving ko sutura, idan ya cancanta.

Aikace-aikace na Dry Granulators:

Pharmaceutical Industry: Dry granulation ne yadu amfani a Pharmaceutical masana'antu don samar da Allunan, capsules, da sauran m sashi siffofin.Yana ba da damar matsawa kai tsaye na foda na miyagun ƙwayoyi a cikin granules, haɓaka haɓakawa, daidaituwa, da kwamfutar hannu.Busassun granulators sun dace da ƙananan sikelin da kuma samar da magunguna masu girma.

Masana'antar sinadarai: Ana amfani da busasshen granulation a cikin masana'antar sinadarai don samar da takin mai magani, masu kara kuzari, pigments, da sauran samfuran sinadarai.Tsarin yana ba da damar daidaitaccen iko akan kaddarorin granule, kamar girman, yawa, da porosity, tabbatar da daidaiton ingancin samfur da ingantattun halayen kulawa.

Masana'antar Abinci da Nutraceutical: Ana amfani da busasshen granulation a cikin masana'antar abinci da masana'antar gina jiki don samar da sinadarai na granular, abubuwan abinci, da ƙari na abinci.Yana ba da izini don ƙirƙira gaurayawan al'ada, tsarin sakin sarrafawa, da haɓaka haɓaka don ingantaccen aiki da sauƙin mabukaci.

Foda Metallurgy: Dry granulation taka muhimmiyar rawa a foda metallurgy, inda karfe foda aka compacted da granulated don samar da feedstocks ga m matakai kamar compaction, sintering, da kuma siffata.Dry granulation kara habaka kwarara Properties, yawa, da kuma uniformity na karfe foda, sauƙaƙe su handling da na gaba masana'antu ayyukan.

Ƙarshe:

Busassun granulators suna ba da ingantacciyar inganci da farashi mai inganci na busassun kayan busassun ba tare da buƙatar masu ɗaure ruwa ko kaushi ba.Tare da fa'idodi irin su ingantaccen kwanciyar hankali, tanadin farashi, da kaddarorin granule da za a iya daidaita su, busassun busassun busassun sun sami aikace-aikace a cikin masana'antu daban-daban, gami da magunguna, sinadarai, abinci, abubuwan gina jiki, da ƙarfe foda.Ta amfani da busassun granulators, masana'antun za su iya cimma daidaiton ingancin samfur, haɓaka halayen sarrafawa, da haɓaka hanyoyin masana'anta.