Muna da cikakkiyar gogewa a layin samar da taki.Mu ba kawai mayar da hankali ga kowane tsari mahada a cikin samar tsari, amma kuma ko da yaushe gane aiwatar da cikakken bayani na kowane dukan samar line da smoothly cimma interlinking.Muna samar da hanyoyin samar da layin samarwa na musamman bisa ga ainihin bukatun abokan ciniki.

Cikakken tsarin samarwa yana ɗaya daga cikin manyan fa'idodin haɗin gwiwar ku tare da masana'antar Yuzheng Heavy.Mun samar da tsari zane da kuma yi na cikakken sa na drum granulation samar Lines.

Complex taki wani hadadden taki ne mai dauke da sinadarin nitrogen, phosphorus da potassium, wanda ake hadawa gwargwadon wani kaso na taki daya da hada shi ta hanyar halayen sinadaran.Abubuwan da ke cikin sinadirai iri ɗaya ne kuma girman barbashi iri ɗaya ne.A fili taki samar line yana da fadi da karbuwa zuwa granulation na daban-daban fili taki albarkatun kasa.

Haɗe-haɗe taki yana da halaye na granulation iri ɗaya, launi mai haske, ingantaccen inganci, da sauƙin narkewa don amfanin gonaki.Musamman, yana da ingantacciyar lafiya ga tsaba don shuka taki.Ya dace da kowane irin ƙasa da alkama, masara, kankana da 'ya'yan itace, gyada, kayan lambu, wake, furanni, itatuwan 'ya'yan itace da sauran amfanin gona.Ya dace da takin tushe, taki, korar taki, taki da ban ruwa.

Raw kayan don samar da takin mai magani sun hada da urea, ammonium chloride, ammonium sulfate, ammonia ruwa, ammonium monophosphate, diammonium phosphate, potassium chloride, potassium sulfate, ciki har da wasu yumbu da sauran abubuwan cikawa.Ana ƙara kayan halitta iri-iri bisa ga buƙatun ƙasa:

1. Najasar dabba: kaza, takin alade, takin tumaki, wakar shanu, takin doki, takin zomo, da sauransu.

2, sharar masana'antu: inabi, vinegar slag, rogo saura, sugar saura, biogas sharar gida, Jawo saura, da dai sauransu.

3. Sharar noma: bambaro, garin waken soya, garin auduga, da sauransu.

4. Sharar gida: dattin kicin

5, sludge: sludge na birni, sludge kogi, sludge tace, da dai sauransu.

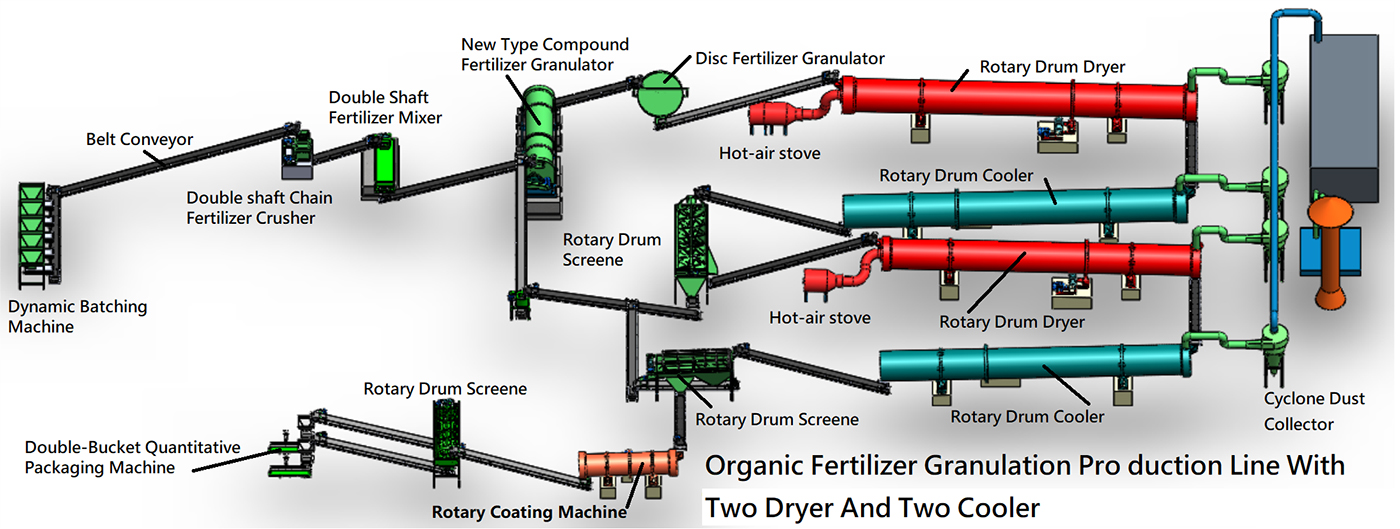

Layin samar da taki na fili an sanye shi da wani abu mai ƙarfi, mai na'urar axis guda biyu, sabon mahaɗan taki granulator, injin murƙushe sarƙoƙi na tsaye, na'urar bushewa da bushewa, injin bushewa na ganga, injin sarrafa ganga, na'ura mai ɗaukar hoto, mai tara ƙura, marufi ta atomatik. inji da sauran kayan taimako.

A matsayin ƙwararrun masana'anta na kayan aikin samar da taki, muna ba abokan ciniki tare da layin samarwa tare da ton 10,000 a kowace shekara zuwa tan 200,000 a kowace shekara.

1. The granulation kudi ne kamar yadda high as 70% tare da ci-gaba drum granulation inji.

2. Maɓalli masu mahimmanci sun ɗauki kayan da ba su da lalacewa da lalata, kuma kayan aiki suna da tsawon rayuwar sabis.

3. Rotary drum granulator an lullube shi da silicone ko faranti na bakin karfe, kuma kayan ba shi da sauƙi don tsayawa ga bangon ciki na na'ura.

4. Tsararren aiki, kulawa mai dacewa, babban inganci da ƙarancin amfani da makamashi.

5. Yi amfani da mai ɗaukar bel don haɗa dukkan layin samarwa don cimma ci gaba da samarwa.

6. Yi amfani da ɗakuna guda biyu na cire ƙura don kula da iskar wutsiya don kare muhalli.

7. Rarraba na aiki na sieves guda biyu yana tabbatar da cewa girman barbashi daidai ne kuma ingancin ya cancanta.

8. Uniform hadawa, bushewa, sanyaya, shafi da sauran matakai sa ƙãre samfurin mafi girma a cikin inganci.

Tsari kwarara na fili taki samar line: albarkatun kasa → albarkatun kasa hadawa → granulation → bushewa → sanyaya → gama samfurin nunawa → roba barbashi → shafi → gama samfurin marufi → ajiya.Lura: wannan layin samarwa don tunani ne kawai.

Sinadaran danye:

Dangane da buƙatun kasuwa da sakamakon ƙayyadaddun ƙasa na gida, urea, ammonium nitrate, ammonium chloride, ammonium thiophosphate, ammonium phosphate, diammonium phosphate, calcium mai nauyi, potassium chloride (potassium sulfate) da sauran albarkatun ƙasa ana rarraba su cikin wani kaso.Ana amfani da ƙari, abubuwan ganowa, da dai sauransu azaman sinadirai a cikin wani yanki ta hanyar ma'aunin bel.Dangane da tsarin dabara, duk kayan aikin da ake buƙata suna gudana daidai gwargwado daga bel zuwa mahaɗa, tsari da ake kira premixes.Yana tabbatar da daidaiton tsari kuma yana samun ingantaccen ci gaba da sinadaran.

1. Mix:

Kayan albarkatun da aka shirya an gauraye su sosai kuma suna motsawa daidai, suna aza harsashin inganci da inganci mai inganci.Ana iya amfani da mahaɗin kwance ko mahaɗar faifai don haɗawa iri ɗaya da motsawa.

2. Girma:

Ana jigilar kayan bayan haɗawa da murkushewa daidai gwargwado daga mai ɗaukar bel zuwa sabon mahaɗin taki granulator.Tare da ci gaba da juyawa na drum, kayan suna samar da motsi mai motsi tare da wata hanya.A ƙarƙashin matsa lamba na extrusion da aka haifar, an sake haɗuwa da kayan cikin ƙananan ƙwayoyin cuta kuma an haɗa su zuwa foda da ke kewaye don a hankali ya samar da siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar siffar.Granules.

3. Busassun granules:

Ana buƙatar busasshen kayan granulation kafin ya iya saduwa da buƙatun abun ciki na danshi.Lokacin da na'urar bushewa ta juya, farantin ɗagawa na ciki ya ci gaba da ɗagawa yana jefa ɓangarorin gyare-gyaren, don kayan yana da cikakkiyar hulɗa tare da iska mai zafi don cire danshi daga gare ta, don cimma burin bushewa iri ɗaya.Yana ɗaukar tsarin tsabtace iska mai zaman kansa don fitar da iskar gas a tsakiya da adana makamashi da rage amfani.

4. Sanyi na Granule:

Bayan an bushe sassan kayan, ana buƙatar a aika su zuwa mai sanyaya don sanyaya.Ana haɗa mai sanyaya ta hanyar mai ɗaukar bel zuwa na'urar bushewa.Sanyaya zai iya cire ƙura, inganta yanayin sanyaya da amfani da makamashi mai zafi, da kuma ƙara cire danshi daga barbashi.

5. Nunawa:

Bayan an sanyaya abubuwan da aka sanyaya, duk mai kyau da manyan barbashi suna nunawa ta hanyar abin nadi.Samfuran da ba su cancanta ba da aka keɓe daga mai ɗaukar bel zuwa blender ana zuga su kuma a sake juye su tare da albarkatun ƙasa.Za a kai samfurin da aka gama zuwa injin rufe taki.

6. Ma'ana:

An fi amfani da shi don amfani da fim ɗin kariya na uniform zuwa saman ɓangarorin da aka gama da su don inganta rayuwar barbashi yadda ya kamata da kuma sanya barbashi sumul.Bayan rufewa, shine hanyar haɗin gwiwa ta ƙarshe a cikin dukkanin tsarin samarwa - marufi.

7. Marufi:

Wannan tsari yana ɗaukar na'ura mai ƙididdigewa ta atomatik.Na'urar tana kunshe da injin aunawa ta atomatik, tsarin jigilar kaya, na'urar rufewa, da sauransu. Hakanan zaka iya saita hoppers bisa ga bukatun abokin ciniki.Yana iya gane marufi na adadi mai yawa kamar takin gargajiya da taki.