Cikakken kayan aikin samarwa don takin mai magani

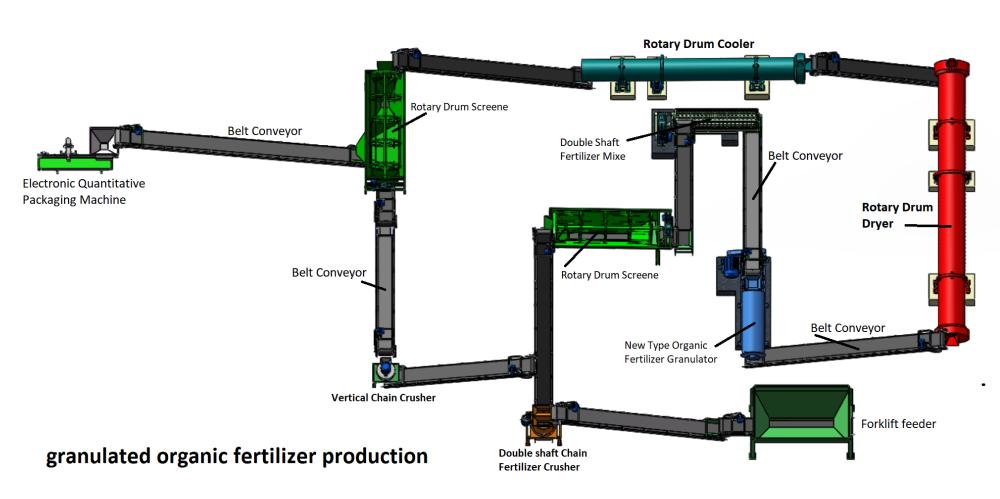

Cikakkun kayan aikin samarwa don takin mai magani yawanci sun haɗa da injuna da kayan aiki masu zuwa:

1.Crushing kayan aiki: An yi amfani da shi don murkushe albarkatun ƙasa a cikin ƙananan ƙwayoyin cuta don sauƙaƙe haɗuwa da granulation.Wannan ya haɗa da crumbleers, grinders, da shredders.

2.Mixing kayan aiki: An yi amfani da shi don haɗa nau'ikan albarkatun kasa daban-daban don ƙirƙirar haɗuwa mai kama.Wannan ya haɗa da mahaɗar kwance, mahaɗar tsaye, da mahaɗar diski.

3.Granulating kayan aiki: An yi amfani dashi don canza kayan da aka haɗe zuwa granules ko pellets.Wannan ya haɗa da granulators na ganga mai jujjuya, granulators na nadi biyu, da granulators pan.

4.Drying kayan aiki: An yi amfani dashi don rage yawan danshi na granules bayan granulation, yana sa su sauƙi don rikewa da adanawa.Wannan ya haɗa da na'urorin bushewa, na'urar busar da ruwa mai ruwa, da busar da bel.

5.Cooling kayan aiki: Ana amfani da su don kwantar da granules bayan bushewa don hana su haɗuwa tare ko rushewa.Wannan ya haɗa da na'urorin sanyaya rotary, na'urorin sanyaya gadaje masu ruwa da tsaki, da na'urorin sanyaya-ƙasa.

6.Screening kayan aiki: An yi amfani da shi don cire duk wani nau'i mai girma ko ƙananan ƙira daga samfurin ƙarshe, tabbatar da cewa samfurin yana da daidaito da inganci.Wannan ya haɗa da allon jijjiga da allon rotary.

7.Coating kayan aiki: An yi amfani da shi don ƙara kayan kariya ga granules, wanda zai iya inganta juriya ga danshi, caking, da sauran nau'i na lalata.Wannan ya haɗa da masu suturar ganga da masu riguna na gado.

8.Packing kayan aiki: An yi amfani da shi don kunshin samfurin ƙarshe a cikin jaka ko kwantena don ajiya da rarrabawa.Wannan ya haɗa da injunan jakunkuna ta atomatik, injunan cikawa, da palletizers.

Cikakken kayan aikin samar da taki na fili za a iya keɓance su don dacewa da ƙarfin samarwa daban-daban da buƙatu, dangane da takamaiman bukatun mai amfani.An ƙera kayan aikin ne don samar da ingantattun taki masu inganci waɗanda ke samar da daidaiton matakan gina jiki ga amfanin gona, da taimakawa wajen haɓaka amfanin gona da inganta lafiyar ƙasa.