Hadaddiyar taki, wanda aka fi sani da taki, taki ne mai dauke da duk wani sinadari biyu ko uku na sinadaran amfanin gona, irin su nitrogen, phosphorus da potassium, wanda aka hada ta hanyar halayen sinadaran ko hanyoyin hadawa;mahadi takin mai magani na iya zama powdery ko granular.Haɗin takin yana ƙunshe da manyan sinadirai masu aiki, yana da sauƙin narkewa cikin ruwa, yana rushewa da sauri, kuma yana da sauƙi a shafe shi ta hanyar tushen.Saboda haka, ana kiransa "taki mai sauri".Ayyukansa shine saduwa da buƙatu da ma'auni na nau'o'in abubuwan gina jiki a cikin yanayi daban-daban na samarwa.

Layin samar da takin zamani na ton 50,000 a duk shekara hade ne na kayan aiki na zamani.Farashin samarwa ba su da inganci.Za'a iya amfani da layin samar da taki mai hade don granulation na nau'ikan albarkatun ƙasa daban-daban.A ƙarshe, ana iya shirya takin mai magani tare da ƙima da ƙima daban-daban bisa ga ainihin buƙatun, yadda ya kamata ya cika abubuwan gina jiki da amfanin gona ke buƙata, da magance sabani tsakanin buƙatun amfanin gona da wadatar ƙasa.

Layin Samar da Taki Mai Haɗuwa ana amfani da shi musamman don samar da takin mai magani na nau'i daban-daban kamar potassium s nitrogen, phosphorus potassium perphosphate, potassium chloride, granular sulfate, sulfuric acid, ammonium nitrate da sauran dabaru daban-daban.

A matsayin ƙwararrun masana'anta na kayan aikin samar da taki, muna ba abokan ciniki tare da kayan aikin samarwa da mafita mafi dacewa don buƙatun ƙarfin samarwa daban-daban kamar ton 10,000 a kowace shekara zuwa ton 200,000 a kowace shekara.Cikakken saitin kayan aiki yana da ƙima, m da kimiyya, tare da aikin barga, kyakkyawan sakamako na ceton makamashi, ƙarancin kulawa da aiki mai dacewa.Shi ne mafi kyawun zaɓi don masana'antun taki mai gauraya (gauraye taki).

Layin samar da taki mai haɗe-haɗe na iya samar da taki mai girma, matsakaita da ƙasa kaɗan daga amfanin gona daban-daban.Gabaɗaya, takin mai magani ya ƙunshi aƙalla abubuwa biyu ko uku (nitrogen, phosphorus, potassium).Yana da halaye na babban abun ciki na gina jiki da ƴan illa.Hadaddiyar taki na taka muhimmiyar rawa wajen daidaiton hadi.Yana iya ba kawai inganta hadi yadda ya dace, amma kuma inganta barga da kuma high yawan amfanin gona na amfanin gona.

Aikace-aikacen layin samar da taki:

1. Samar da tsari na sulfur-baged urea.

2. Daban-daban samar da matakai na Organic da inorganic fili da takin mai magani.

3. Acid taki tsari.

4. Powdered masana'antu inorganic taki tsari.

5. Tsarin samar da urea mai girma.

6. Samar da tsari na matrix taki don seedlings.

Danyen kayan da ake samu don samar da taki:

Abubuwan da ake amfani da su na layin samar da taki sune urea, ammonium chloride, ammonium sulfate, ammoniya ruwa, ammonium phosphate, diammonium phosphate, potassium chloride, potassium sulfate, gami da wasu yumbu da sauran abubuwan filaye.

1) Nitrogen takin mai magani: ammonium chloride, ammonium sulfate, ammonium thio, urea, calcium nitrate, da dai sauransu.

2) Potassium takin mai magani: potassium sulfate, ciyawa da ash, da dai sauransu.

3) Phosphorus takin mai magani: calcium perphosphate, nauyi calcium perphosphate, calcium magnesium da phosphate taki, phosphate ore foda, da dai sauransu.

Layin samar da takin zamani rotary drum granulation galibi ana amfani dashi don samar da taki mai ɗimbin yawa.Za a iya amfani da granulation na faifai zagaye don samar da fasahar takin zamani mai girma da ƙarancin tattarawa, haɗe da fasahar hana cunkoso taki, fasahar samar da taki mai yawan nitrogen, da dai sauransu.

Layin samar da takin zamani na masana'anta yana da halaye masu zuwa:

Ana amfani da albarkatun kasa sosai: ana iya samar da takin mai magani bisa ga tsari daban-daban da kuma adadin takin mai magani, sannan kuma ya dace da samar da takin gargajiya da na inorganic.

Matsakaicin matsakaicin nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau’in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in halitta yana da girma: sabon tsari na iya cimma matsakaicin yanayi fiye da 90% zuwa 95%, kuma fasahar bushewar iska mai ƙarancin zafin jiki na iya sa ƙwayoyin ƙwayoyin cuta su kai ƙimar rayuwa sama da 90%.Samfurin da aka gama yana da kyau a bayyanar kuma har ma da girman, 90% wanda shine barbashi tare da girman girman 2 zuwa 4mm.

Tsarin aiki yana da sassauƙa: ana iya daidaita tsarin samar da taki na fili bisa ga ainihin kayan albarkatun ƙasa, dabara da rukunin yanar gizon, ko kuma ana iya tsara tsarin da aka keɓance bisa ga ainihin bukatun abokan ciniki.

Matsakaicin adadin abubuwan gina jiki na samfuran ƙãre sun kasance barga: ta hanyar ma'auni ta atomatik na sinadarai, daidaitaccen ma'auni na daskararru daban-daban, ruwaye da sauran albarkatun ƙasa, kusan kiyaye kwanciyar hankali da tasirin kowane mai gina jiki a duk lokacin aiwatarwa.

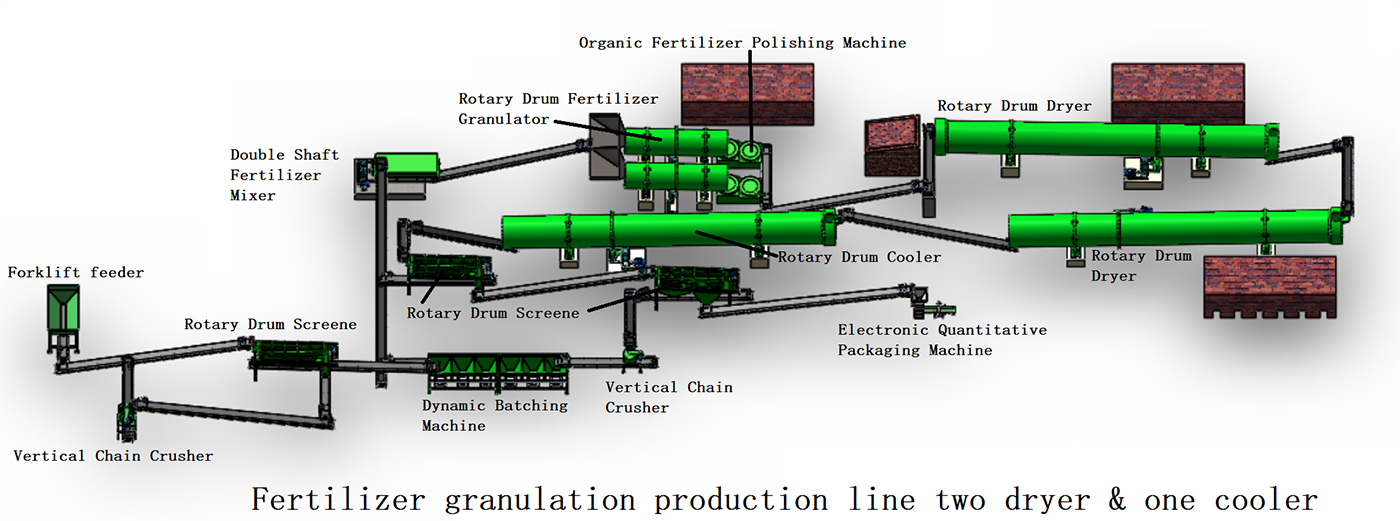

A tsari ya kwarara daga cikin hadaddun taki samar line yawanci za a iya raba zuwa: albarkatun kasa sinadaran, hadawa, murkushe nodules, granulation, farko nunawa, barbashi bushewa, barbashi sanyaya, sakandare nunawa, ƙãre barbashi shafi, da kuma adadi marufi na ƙãre kayayyakin.

1. Kayan danye danye:

Dangane da buƙatun kasuwa da sakamakon ƙayyadaddun ƙasa na gida, urea, ammonium nitrate, ammonium chloride, ammonium thiophosphate, ammonium phosphate, diammonium phosphate, calcium mai nauyi, potassium chloride (potassium sulfate) da sauran albarkatun ƙasa ana rarraba su cikin wani kaso.Ana amfani da ƙari, abubuwan ganowa, da dai sauransu azaman sinadirai a cikin wani yanki ta hanyar ma'aunin bel.Dangane da tsarin dabara, duk kayan aikin da ake buƙata suna gudana daidai gwargwado daga bel zuwa mahaɗa, tsari da ake kira premixes.Yana tabbatar da daidaiton tsari kuma yana samun ingantaccen ci gaba da sinadaran.

2. Mix:

Kayan albarkatun da aka shirya an gauraye su sosai kuma suna motsawa daidai, suna aza harsashin inganci da inganci mai inganci.Ana iya amfani da mahaɗin kwance ko mahaɗar faifai don haɗawa iri ɗaya da motsawa.

3. Rushewa:

Ana murƙushe lumps a cikin kayan bayan haɗuwa a ko'ina, wanda ya dace don sarrafa granulation na gaba, galibi ta amfani da murkushe sarkar.

4. Girma:

Ana jigilar kayan bayan haɗawa daidai kuma an niƙa shi zuwa injin granulation ta hanyar jigilar bel, wanda shine babban ɓangaren layin samar da taki.Zaɓin granulator yana da matukar muhimmanci.Ma'aikatar mu tana samar da faifan diski, granulator na drum, abin nadi ko granulator taki.

5. Nunawa:

Ana sieved barbashi, kuma abubuwan da ba su cancanta ba ana mayar da su zuwa babban haɗin gwiwa da motsawa don sake sarrafawa.Gabaɗaya, ana amfani da injin abin nadi.

6. Marufi:

Wannan tsari yana ɗaukar na'ura mai ƙididdigewa ta atomatik.Na'urar tana kunshe da injin aunawa ta atomatik, tsarin jigilar kaya, na'urar rufewa, da sauransu. Hakanan zaka iya saita hoppers bisa ga bukatun abokin ciniki.Yana iya gane yawan marufi na kayan girma kamar takin gargajiya da taki, kuma an yi amfani dashi sosai a masana'antar sarrafa abinci da layin samar da masana'antu.